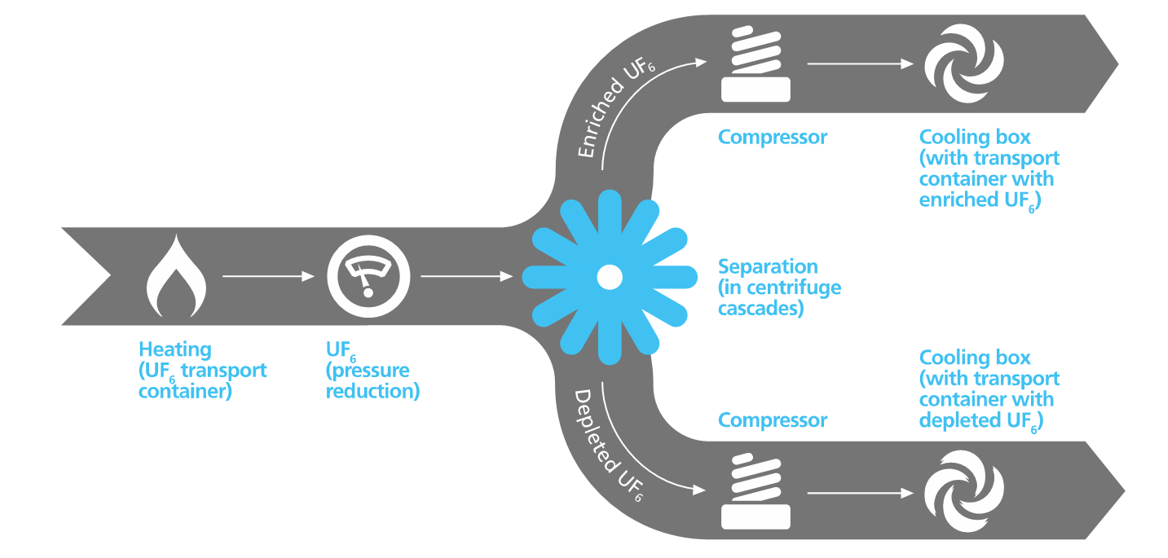

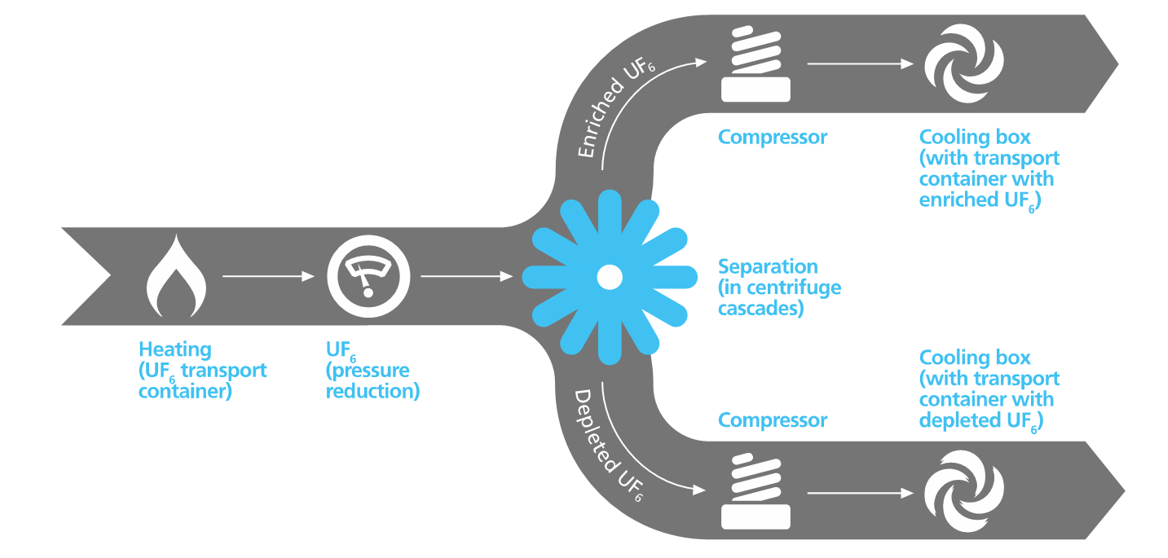

1. Heating uranium hexafluoride (UF6) to turn it into a gas

Approved suppliers deliver UF6 to our enrichment facilities in international, standardised transport containers.

UF6 is solid at ambient temperature. At our enrichment facilities, we connect the transport container holding UF6 to the plant feed system. We then heat the container to vaporise the UF6 and turn it into gas at sub atmospheric pressure.

2. Spinning UF6 in high speed centrifuges to enrich it

We feed the UF6 gas into a centrifuge casing containing a cylindrical rotor which spins at high speed, separating uranium’s two isotopes. The heavier isotope uranium238 (U238) is forced closer to the cylinder wall than the lighter uranium235 (U235). As a result, the UF6 gas closer to the wall is depleted in U235 and the UF6 gas nearer the rotor axis is slightly enriched in U235. We repeat the process many times in a series of centrifuges, known as cascades, until we achieve the desired levels of U235 enrichment to meet our customers’ specifications, typically between 3% and 5%.

3. Compressing and cooling the enriched uranium

We feed the enriched uranium from the centrifuge cascades into a compressor and then into a cooling box containing a cylinder. As it cools, the UF6 vapour solidifies within cylinders. We homogenise the UF6 in the cylinders and check the quality of a sample before delivering it to customers. We weigh all cylinders to comply with the accounting and tracking requirements of the European Atomic Energy Community, United States Nuclear Regulatory Commission and the International Atomic Energy Agency.

4. Storing and converting depleted uranium

The UF6 gas closer to the centrifuge wall is partially depleted in U235. This by-product is known as tails. We collect and cool tails in a cooling box containing a cylinder, weighing it to ensure all material can be accounted for. Tails still contain a low concentration of U235 and can be re-enriched if economically viable.

We store tails at our enrichment facilities in internationally approved containers pending deconversion to a chemically stable form, uranium oxide (U3O8), for long term storage for future enrichment or final disposal. Our Tails Management Facility is responsible for deconversion and converts UF6 to U3O8. This process also creates hydrofluoric acid, a valuable chemical used globally by industry.

Find out more about our Tails Management Facility here.